What is the difference between horizontal and vertical form fill seal machine?

Apr 15,2024 | Views: 1437

Horizontal and vertical form-fill-seal (FFS) machines are both commonly used in packaging applications, but they differ in their orientation and the types of products they are best suited for.

Suitable Products: These machines are typically used for packaging solid items such as bars, biscuits, bread, and other similar products. They can also handle liquids and powders but are often less efficient for these types of products compared to vertical form fill seal machines.

Packaging Process: The packaging film is unwound horizontally, and the product is fed into the film, which is then sealed and cut horizontally. This process is efficient for products that can be easily loaded from the top.

Advantages: Horizontal FFS machines are often preferred for their versatility in handling a wide range of product shapes and sizes. They can accommodate larger products and are suitable for high-speed packaging operations.

Suitable Products: These machines are commonly used for packaging granular or powdered products such as coffee, snacks, rice, sugar, and similar items. They can also handle liquids and semi-liquids efficiently.

Packaging Process: The packaging film is unwound vertically, and the product is fed into the film, which is then formed, sealed, and cut vertically. This process is efficient for products that can be dropped into the packaging vertically.

Advantages: Vertical FFS machines are often preferred for their high-speed operation, especially for small to medium-sized products. They have a smaller footprint compared to horizontal machines, making them suitable for space-limited production environments.

Prev: What does a form fill seal machine do?

Next: How does a vertical form fill seal machine work?

Horizontal Form-Fill-Seal (HFFS) Machines:

Orientation: Horizontal FFS machines operate with the product moving horizontally through the packaging process.Suitable Products: These machines are typically used for packaging solid items such as bars, biscuits, bread, and other similar products. They can also handle liquids and powders but are often less efficient for these types of products compared to vertical form fill seal machines.

Packaging Process: The packaging film is unwound horizontally, and the product is fed into the film, which is then sealed and cut horizontally. This process is efficient for products that can be easily loaded from the top.

Advantages: Horizontal FFS machines are often preferred for their versatility in handling a wide range of product shapes and sizes. They can accommodate larger products and are suitable for high-speed packaging operations.

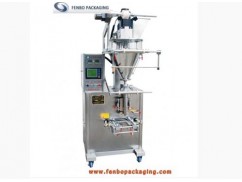

Vertical Form-Fill-Seal (VFFS) Machines:

Orientation: Vertical FFS machines operate with the product moving vertically through the packaging process.Suitable Products: These machines are commonly used for packaging granular or powdered products such as coffee, snacks, rice, sugar, and similar items. They can also handle liquids and semi-liquids efficiently.

Packaging Process: The packaging film is unwound vertically, and the product is fed into the film, which is then formed, sealed, and cut vertically. This process is efficient for products that can be dropped into the packaging vertically.

Advantages: Vertical FFS machines are often preferred for their high-speed operation, especially for small to medium-sized products. They have a smaller footprint compared to horizontal machines, making them suitable for space-limited production environments.